Contactless data transmission

Since the intended purpose is different for each application, it is important to consider not only all of these elements, but also the type of transmission technology your system will use, such as; radio transmission, infrared light modulation, LED lighting modulation or ultrasound. Wireless networks can also be designed to allow only the interconnection of digital systems between them, or to connect sensors with a control system.

Here are some examples of wireless data transmission technologies that, depending on your type of installation, could be very useful for your business.

the slip rings of Kübler

Kübler slip rings guarantee a reliable transmission of electrical energy, analog or digital signals, as well as the transmission of fieldbuses and Industrial Ethernet. Thanks to their modular design, various contact and non-contact technologies, as well as the possibility of combining them with the media passage for air and liquids, you have maximum flexibility in the configuration of your slip ring.

By means of this modular design, the SR085 slip ring can be perfectly adapted to all carousel sizes of textile machines. The reliable contact technology also allows you to transfer fieldbus data via the same slip ring. High vibration resistance, long service life and long maintenance cycles reduce machine downtime. The compact housing and connections are easily accessible and allow for quick and easy installation!

In brief:

- Power, signal and data transmission

- Maximum flexibility due to modular design

- Long service life - made in Germany

- Reliable contact systems

- Non-contact signal transmission

Application examples

Perfect for integration into various types of media, the SR085 can transmit loads and signals in both the pneumatic and hydraulic fields. Its modular design can support up to 21 channels, giving you maximum flexibility.

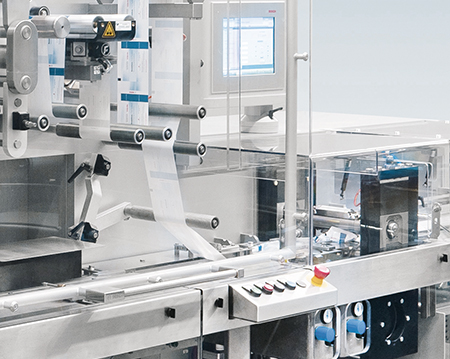

At only 60 mm in size, the SR060 is a compact and economical slip ring that can support up to 3 load channels and 2 signal channels. It can be used to heat and monitor sealing rollers in flow-pack machines. Slip rings that open frequently during use can often lead to carbon abrasion contamination of the brushes and become difficult to clean. The SR060E offers the ideal contamination-free solution with its fully encapsulated plastic housing and IP64 protection to meet the food industry's particularly high requirements for cleanliness and hygiene. In addition, long maintenance cycles of 100 million revolutions round off its strengths and make it the specialist for tubular bag machines.

Turck's inductive couplers

With the non-contact inductive couplers, Turck offers a wear-free alternative to conventional connection technology. The NIC coupler assemblies consist of a primary part on one side of the drive and a secondary part on the sensor/actuator side of the connecDynamic coupling. The primary parts can be combined with as many secondary parts as you need and vice versa.

3 communication solutions are available for the transmission of your signals and data.

Solution 1: Up to two PNP switching signals can be transmitted either from power clamp sets or from two different sensors connected via a splitter or an IO-Link device.

Solution 2: With the main room connected to an IO-Link master. The measurement data from the IOLink sensors can be transmitted bidirectionally. You can also connect to an IO-Link compatible actuator such as a light tower or a TBIL-M1-16DIP I/O concentrator with 16 PNP digital inputs.

Solution 3: By operating the primary part as an IO-Link master, allowing up to eight switching signals to be processed via a hub. All IO-Link communication will be handled internally, requiring no configuration for the user.

NIC couplings are a wear-free alternative to heavily loaded slip rings or mechanical connections. This means longer maintenance intervals, less unscheduled downtime and optimized working hours. Inductive couplers as non-contact connectors also offer you a great deal of freedom of movement, as they offer rotating robots, tools or shafts in their coupled components, from which the sensor signals can be picked up. These inductive couplers can be used in overhead conveyor systems or in the automotive industry...

In short

• Wear-free

• Maximum mounting flexibility thanks to optimum air interface and offset tolerances

• Tool identification with Turck's TBIL I / O-hub

• Stock reduction by multifunction devices

• Fewer suppliers: Couplers, sensors and connectors from a single source

• Reduced downtime thanks to diagnostics in the control system

• Global support through Turck Group's global sales and support channels and Weidmüller's radio telemetry

Weidmüller one-way transmitter/receiver units

Weidmüller's range of unidirectional wireless I/O products can be suitable for connection to a single sensor or a group of sensors. It provides a cost-effective solution for remote system monitoring. These transmitters can also be used in more complex networks as signal receivers. The wireless I/O connects directly (analog) to systems. The signals are transmitted in radio frequency bands.

Wireless I/O, also known as radio telemetry, connects directly to sensor and control signals to transmit signal values via radio. These signals are either created as similar signals or transmitted as a data connection; Ethernet, Profibus, Modbus, etc.

The setup for these wireless networks can be as simple as two units transferring a small number of signals from one point to another, or it can be a complex data acquisition network with multiple "master" interfaces to external systems.

In short

- P-based addressing has unique MESH capability between I/O radios for automatic network healing and reliable data communications

- Unlimited number of repeater hops in a system

- Integrated multi-I/O channels for bi-directional communications

- 902-928 MHz 1W USA/Canada license-free frequency hopping

- Unmatched scalability to allow thousands of I/O points in a single system

- Automatic connection of up to 31 I/O expansion modules (WI-I/O-EX-I-S-XX) per wireless unit

- Simple software upgrade to Ethernet TCP/IP or Modbus

- USB/Ethernet and over-the-air configuration and programming

Sick ISD300 for optical data transmission with long range

The ISD300 optical data transfer enables wireless vehicle communication with a fixed side and offers you a wear-free and flexible solution. This system ensures system availability and reduces maintenance costs through wireless data transfer, elimination of cables and integrated 3-point mounting. With high performance reserve due to immunity to stray light and electromagnetic compatibility (EMC), fast data transfer ensures high system performance. ISD300 includes an optically aligned transmitter and receiver pair capable of bi-directional communication over long distances.

Your benefits

- Wear-free system ensures system availability and reduces maintenance costs

- Faster installation due to wireless data transfer

- Extended ranges and high performance reserve ensure flexibility and reliability

- Low installation costs due to elimination of cables

- High performance reserve through immunity to stray light and electromagnetic compatibility (EMC)

- Fast data transfer guarantees high system performance

- Quick installation with integrated 3-point mounting reduces installation costs

In short

- Range up to 300 m

- Transfer rate up to 2 Mbits/s configurable

- Bargraph for precision alignment

- Optical aid for coarse alignment

- Variety of interfaces: PROFIBUS, Ethernet, DeviceNet, Modbus

In conclusion, there are many products on the market and each of them can bring a lot to your company in terms of productivity and profitability.

For more information on any of these products or to talk to us about one of your optimization projects, contact one of our representatives, they will be able to advise you on the possible applications for your business.

Blog posts