Hazardous area classification

First, it is important to define what is considered a potentially hazardous area. An explosion can be caused by three conditions;

-

The presence of a fuel. This is generally air.

- The presence of a fuel. We are talking about flammable substances in the form of gases, vapors or dusts.

- The contribution of a source of ignition or a very high temperature. The most frequent sources of ignition are: static electricity, lightning, open flames, mechanical sparks, hot surfaces, etc.

According to the National Fire Protection Association, a hazardous location is an area where fire or explosion hazards may exist due to electrical equipment operating in the presence of gases, liquids, flammable vapors, or in the presence of combustible dusts, fibers or fumes. But be aware that even within this definition, the risk of fire or explosion and the conditions necessary to create these hazards vary, depending on the hazardous material that may be present and the probability of the degree of its presence.

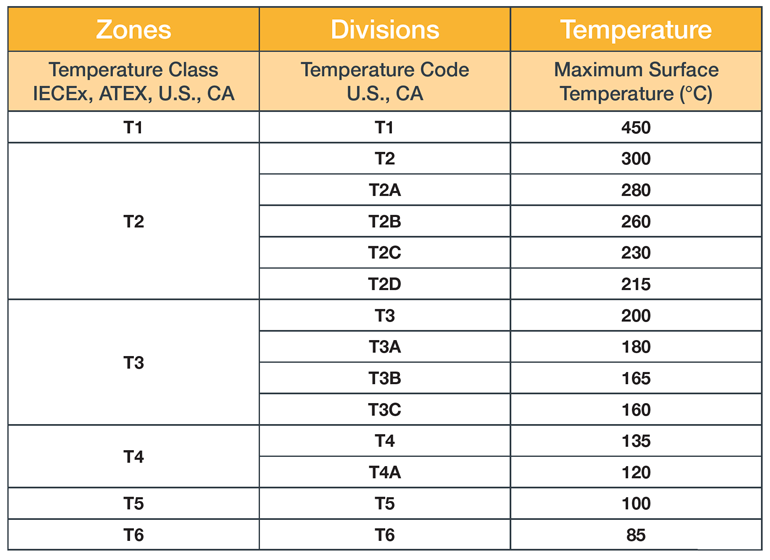

Indeed, the various substances, gases, gas vapors and dusts can self-ignite under the effect of a certain degree of heat. This is called the minimum ignition temperature for dusts and the self-ignition temperature for gases and vapors. The lower these temperatures are, the more dangerous a substance is.

Here is a summary of the temperature classification system.

In response to the importance of selecting equipment that can operate safely in hazardous locations, the United States, Canada and the European Union have developed standard methods for classifying areas where hazardous atmospheres may occur. For the purposes of this blog, we will focus on those in Canada.

The Canadian Electrical Code (CEC) is similar to the NFPA 70 NEC (this standard uses a system of classes and divisions which, when combined, specify the hazardous conditions of an area), providing both class, division and zone classification systems. However, since 1998, the CEC has required that new facilities be classified according to the zone system.

The classes and divisions

The system of classes and divisions used in the NFPA 70 NEC and the Canadian Electrical Code establishes classifications that indicate the hazardous conditions in a specific area. The classes indicate the type of hazardous substance that is or may be present in the air in sufficient quantities to produce explosive or flammable mixtures.

- Class I - flammable gases or vapors

-

Class II - combustible dusts

-

Class III - highly flammable fibres or mists

The divisions indicate the probability that the hazardous substance is capable of producing an explosive or flammable mixture based on its presence.

Division 1

Flammable concentrations of the hazardous substance exist under normal operating conditions and/or where the hazard is caused by frequent maintenance or equipment failure or where readily flammable fibers or chips are handled, manufactured or used.

Division 2

Flammable concentrations of the hazardous substance exist under abnormal operating conditions or when fibers or chips are stored or handled outside the manufacturing process.

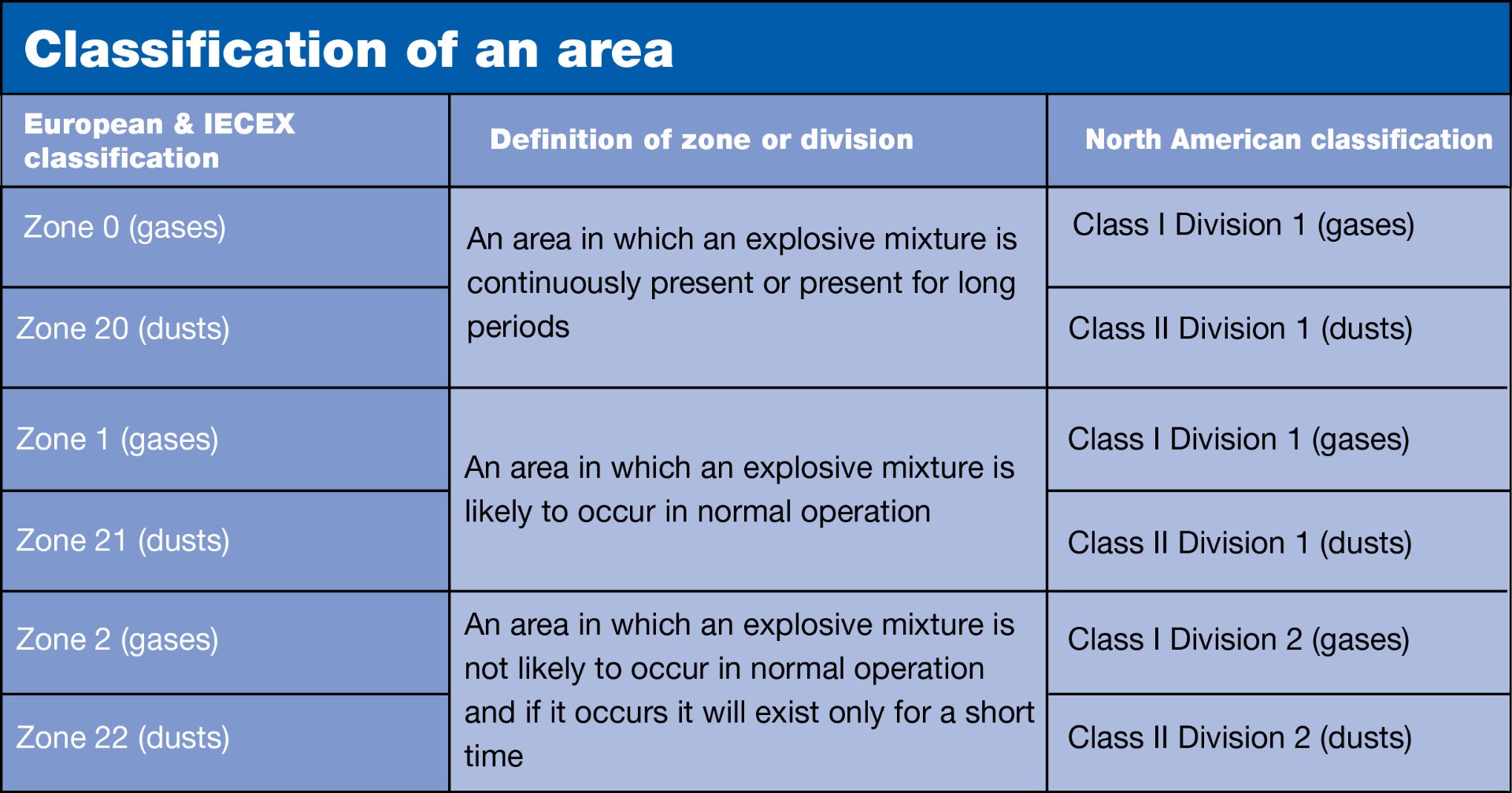

The zones

The zone system for classifying hazardous locations used in NFPA 70 NEC, IEC 60079 and the Canadian Electrical Code indicates the level of probability of a flammable concentration of a hazardous substance potentially being present. There are two sets of zones: Zones 0 to 2 are used for gases, vapors and mists, and Zones 20 to 22 are used for dusts, fibers and fumes.

Gases, vapors and mists

Zone 0

-

Flammable concentrations of flammable gases or vapors are present continuously or for extended periods.

Zone 1

-

Flammable concentrations of flammable gases or vapors are likely to exist under normal operating conditions or may exist frequently due to repairs, maintenance or leaks

-

Equipment is operated in such a manner that failure or malfunction could result in the release of flammable concentrations of flammable gases or vapors and cause failure of the electrical equipment so that the electrical equipment becomes a source of ignition

-

The area is adjacent to a Zone 0 location from which flammable concentrations of vapors could be released.

Zone 2

-

Flammable concentrations of gases or vapors are unlikely to occur under normal operating conditions, or if they do occur, they will only be present for a short period of time

-

Volatile flammable liquids, gases or vapors are confined in closed containers or systems and can only escape through accidental rupture

-

Volatile flammable liquids, gases or vapors are normally prevented by positive mechanical ventilation, but can become hazardous due to system failure

-

The location is adjacent to a Zone 1 from which flammable concentrations of gases or vapors could be released. Dusts, Fibers and Fumes

Zone 20

-

Combustible dusts or flammable fibers or sprays are present continuously or for extended periods.

Zone 21

-

Combustible dust or fibers or flammable fumes are likely to exist under normal operating conditions or may exist frequently due to repairs, maintenance or leaks

-

Equipment is operated in such a manner that failure or malfunction could result in the release of flammable concentrations of combustible dusts or fibers or flammable fumes and cause failure of electrical equipment so that the electrical equipment becomes a source of ignition

-

The site is adjacent to a Zone 20 location from which flammable concentrations of dust or fibers or flammable fumes could be released.

Zone 22

-

Combustible dust or fibers or flammable fumes are unlikely to occur under normal operating conditions, and if they do occur, they will only be present for a short period

-

Combustible dusts or flammable fibers or flyings are confined in closed containers or systems and can escape only as a result of abnormal operation of the equipment with which the dusts or fibers or flyings are handled, processed or used

-

The site is adjacent to a Zone 21 location from which flammable concentrations of dust or fibers or flammable fumes could be released.

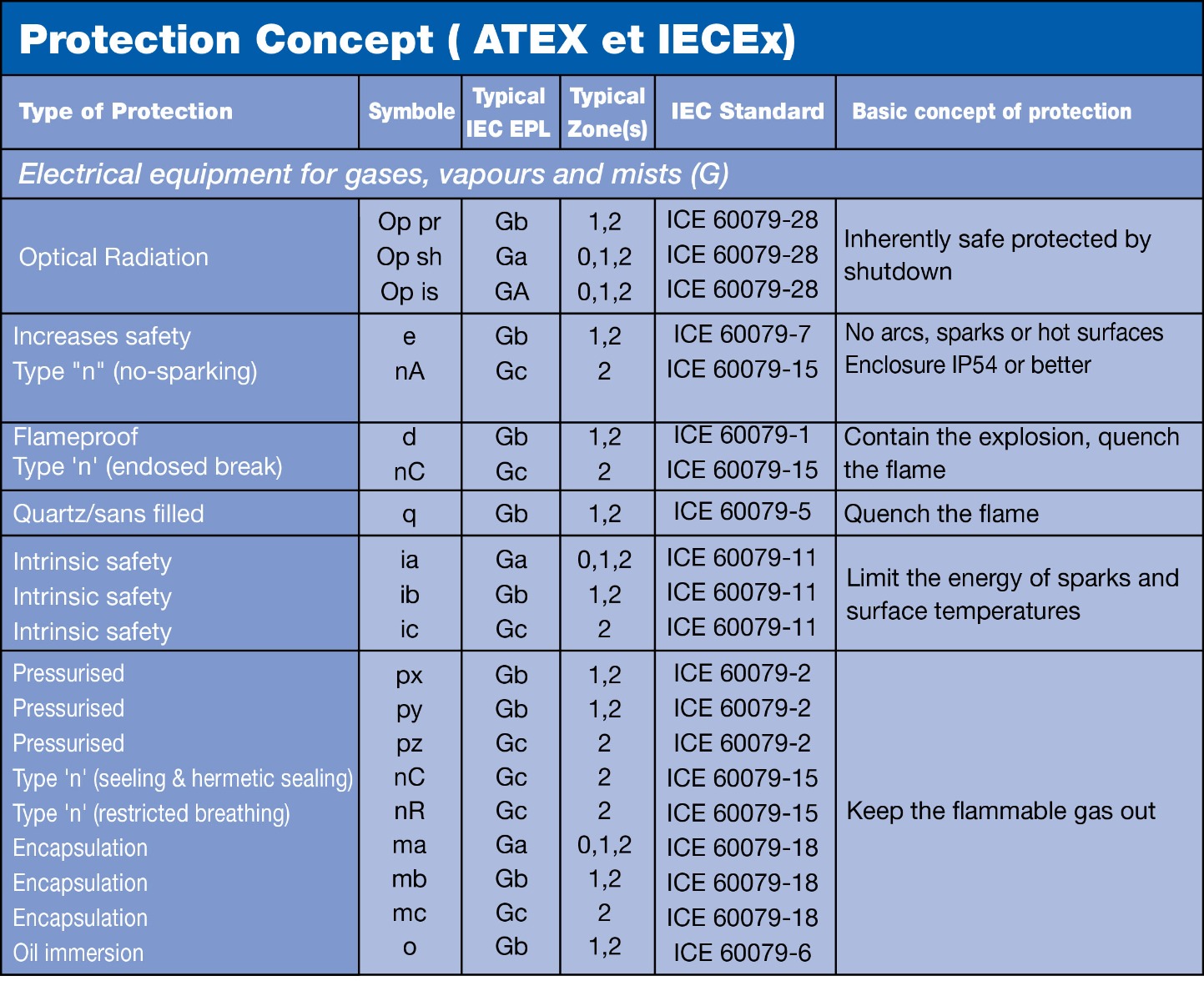

There are also 2 other classifications to consider when electrical equipment is potentially in use and may contain flammable gases, vapors, liquids, dusts or fibers. It is then important to minimize the risk of fire or explosion. One way to do this is to use certified equipment that is suitable for this environment and not likely to cause a fire or explosion. In the European Union, equipment intended for use in these hazardous locations is certified according to the ATEX directives, while in other parts of the world, certification is generally done according to the IECEx system.

ATEX is the European regulatory framework for the manufacture, installation and use of equipment in explosive atmospheres.

IECEx is the International Electrotechnical Commission for certification to standards for equipment intended for use in explosive atmospheres. The development of IECEx was primarily motivated by the need to facilitate international trade in equipment intended for use in potentially hazardous locations while maintaining the required level of safety.

It is important to note that IECEx applies only to electrical equipment intended for use in hazardous environments (unlike ATEX, which applies to both electrical and non-electrical equipment). IECEx also uses more stringent criteria for evidence during the certification process.

Both ATEX and IECEx certifications are aligned with IEC 60079 standards and, in terms of technical requirements, there are few differences between them. Also, the marking systems for ATEX and IECEx are very similar and the two are often combined. It is therefore very common to find both on most equipment. In addition, the ATEX symbol is specific to explosion protection.

Certifications are also divided into two groups and 3 categories. In order to clearly distinguish between equipment intended for use in mines and equipment used in all other domains (sometimes called surface industries). While the equipment categories are directly related to the hazardous area in which the equipment is intended to be used. A lower equipment category number indicates that a higher level of ignition protection is required.

- Group 1 is for equipment used in mines

- Group 2 is for equipment used in all other areas.

The M1 and M2 categories are for equipment used in mines.

- Category 1 refers to equipment intended for use in zones 0 (gas) or 20 (dust).

-

Category 2 refers to equipment intended for use in zone 1 (gas) or 21 (dust).

-

Category 3 refers to equipment intended for use in zones 2 (gas) or 22 (dust).

In short

In closing, we understand that it is not easy to remember everything that is mentioned in this blog, but we invite you to consult the tables that summarize the essential elements to consider when making your acquisitions. For more technical support, contact our representatives. They will be able to advise you on the best products available for your business.

Blog posts