Inductive sensors of factor 1 with IO-Link

IO-Link products are increasingly present in the industry and offer their users many advantages to consider when choosing one of the wide range of sensors available on the market. We have chosen one of them today, the inductive factor 1 sensor with IO-Link.

What is IO-Link?

IO-Link is based on a point-to-point connection between a sensor/actuator and the information system. Until now, the binary connection was only designed to transmit pure switching information, but IO-Link generally allows two bytes to be transmitted via a combined switching and data channel at intervals of 2 ms. In addition to these process values, other information such as parameters or diagnostic messages can be exchanged. In this way, the entire process, right down to the sensors, is covered for integrated communication.

IO-Link does not require any special wiring. The unshielded three-wire industrial cable site can still be used to connect sensors and actuators. It is possible to choose between the standard switching mode and the communication mode.

As a user of IO-Link, you benefit from a multitude of advantages, including lower machine costs, more efficient production and improved availability of your machines and plants.

With the new uprox® IO-Link, Turck offers its Factor 1 sensors with the highest switching distances with IO-Link. The functions of the two outputs 1 and 2 can be set independently of each other (PNP, IO-Link) and are very flexible. The switching distance and hysteresis can be set individually or separately for each output in order to replace two sensors with one uprox®. The integrated temperature monitoring site facilitates preventive maintenance by early detection of faults during factory installation when abnormal temperatures occur.

Your benefits

Cost reduction

The simple configuration allows you to adapt the sensors to your requirements in a flexible and variable way. You can define the output functions and the actual switching distances. Each switching distance is also adjustable and can be executed sequentially in combination with an IO-Link master. This enables the sensor to simulate a kind of low-resolution analog mode.

In addition, the sensors include all the advantages of uprox®3 such as the factor 1 with the highest switching distances and offers an excellent magnetic field strength. The reduction of variants can thus minimize your procurement, storage and administration costs.

Production efficiency

The parameterizable inductive sensors of factor 1 communicate via a standard IO-Link interface and are supplied with a structured configuration file (IODD) that is identical for all uprox® sensors. This ensures simple handling before, during and after commissioning. The intelligent tool identification function using the 32-byte application-specific tag enables greater efficiency in production control.

Improved availability through diagnostics

The integrated temperature measurement provides diagnostic functions for the sensor and the application area around the sensor. The temperature is read and measured by the sensor. User-defined temperature limits can also be configured within the framework of maximum and minimum, physical and technical temperature and output as alarms via the process data in the temperature management system. Warnings can be issued as alarms via the process data if the limits are exceeded. This allows you to prevent possible failures of the cooling systems or imminent temperature-related damage.

The possibility of configuring two separate switching points means that in special applications the uprox® IO-Link can replace two conventional sensors for monitoring different positions. This makes it possible, for example, to diagnose the open/closed brake status indication with integrated wear monitoring until a system failure occurs.

Switching distance

uprox® IO-Link sensors can be flexibly and individually configured to meet the requirements of the application. For example, the switching distance can be changed as a percentage within the physically defined area. Through sequential queries of all switching points, a low-resolution analog signal is produced.

Output function

Any desired combination of functions on the two outputs can be configured via the IO Link interface. Whether PNP, NC, NPN, NO, or both at the same time or complementary, many combinations are possible!

Input/output delay

The adjustable input/output delay between 0 and 60 seconds ensures that unwanted default pulses are reliably removed from the application.

Rotation speed/Pulse divider

With the integrated start delay or the variable pulse divider, the uprox® IO-Link sensors are ideally suited for measuring rotational speed or monitoring a rotationally symmetrical application, as well as for use in packaging plants.

Temperature control

The temperature monitoring built into each sensor allows condition monitoring to be used directly on the application. The minimum and maximum temperature limits can be simply adjusted to the customer's requirements and are output as a process signal.

Identification

The 32-byte application-specific label allows each sensor to be identified individually, thus enabling clear identification of the application.

In brief :

Reduction of machine costs

■ Reduced storage due to configurable multi-function devices.

■ Single I/O module and economical standard cable.

■ Low number of inputs/outputs possible.

■ Devices with display and buttons are no longer necessary.

■ Reduced engineering and installation costs and automatic documentation of device parameters during engineering work.

More efficient production processes

■ Simple parameter changes when replacing devices.

■ Faster parameter set changes for switching thresholds, amplification, sensitivity, etc. for different production conditions.

■ Faster and more reliable tool changes.

Increased availability of machines and installations.

■ Extended status information and diagnostic possibilities in the plant allow for a drastic reduction in machine downtime.

■ Extended information enables cost-saving measures such as predictive maintenance and asset management

■ Automatic acceptance of parameterization enables replacement of devices with fewer skilled personnel.

Field of application

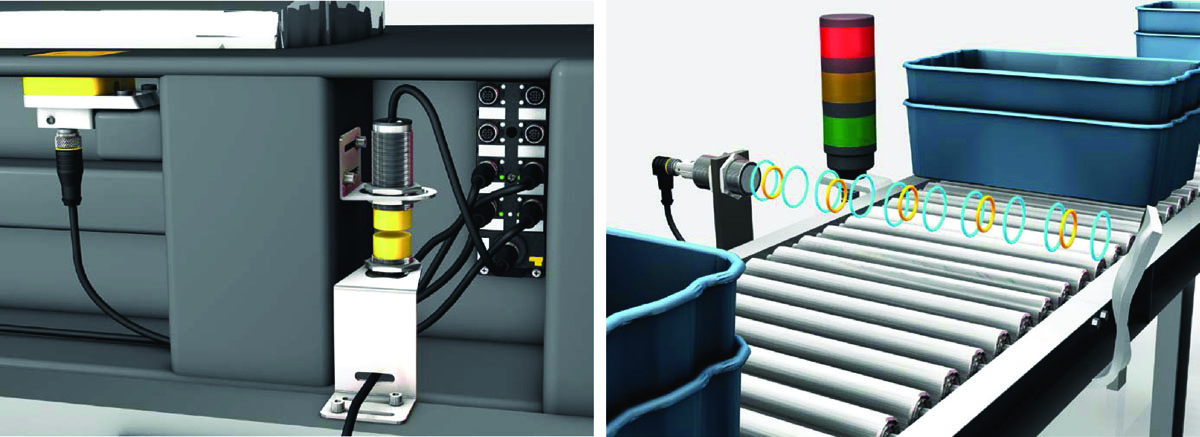

uprox® IO-Link sensors can be used in many application areas, here are some of them

For the transmission of signals in the production of gearboxes on the differential production line of an automotive supplier, for the detection of positions in fairground rides, for the recording of the movement of machinery balances, for the communication of data in silencers, for the contactless transmission of data and energy, for preventive maintenance on conveyor belts.

But also in many applications, such as tools used by robots, on workpiece carriers or in the identification of press tools, where the fixed part of the machine and the tool must be connected mechanically and electrically for the transmission of energy.

For more information on any of these products or to talk to us about one of your optimization projects, contact one of our representatives, they will be able to advise you on the possible applications for your company or your project.

Blog posts