2D-LiDAR LMS4000 sensor

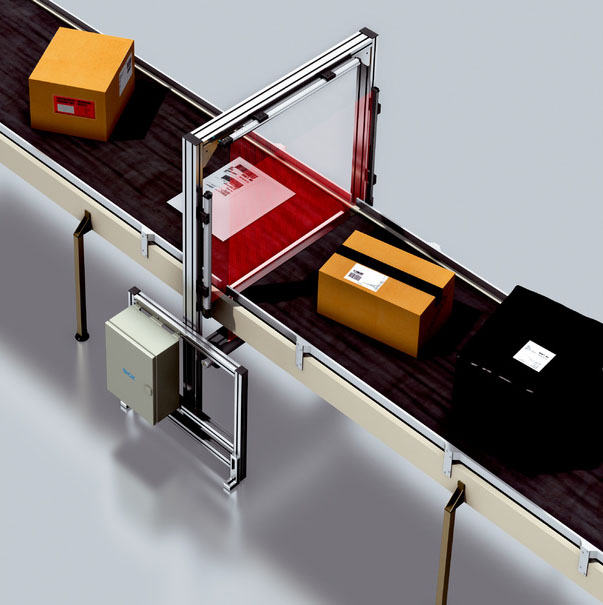

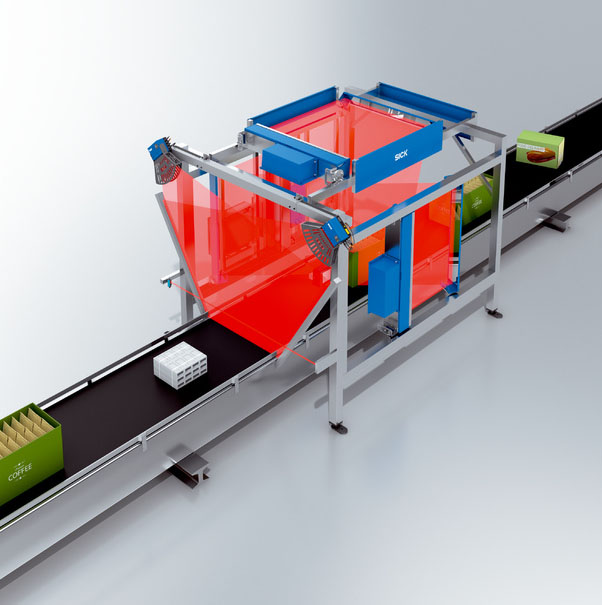

In one of our latest blogs we looked at SICK's VMS4x00 / 5x00 Tracking and Tracing System. Even though this product performs very well, you may need more precision when entering your data during your logistics processes. That's why we always offer the 2D-LiDAR LMS400 sensor from SICK. It is particularly effective in determining the weight and dimensions of cubic-shaped and irregular objects, whose surfaces may be transparent, wrapped in film, or very dark. It can also identify objects with barcodes, matrix codes or RFID at a conveyor speed of up to 4 m / s on flat conveyor belts, cross belt and tray conveyors. This data enables overall safe subsequent processes to be carried out, warehouse optimization and transport processes to be organized efficiently. Depending on its application, it remains reliable and stable up to ambient temperatures down to - 30 ° C.

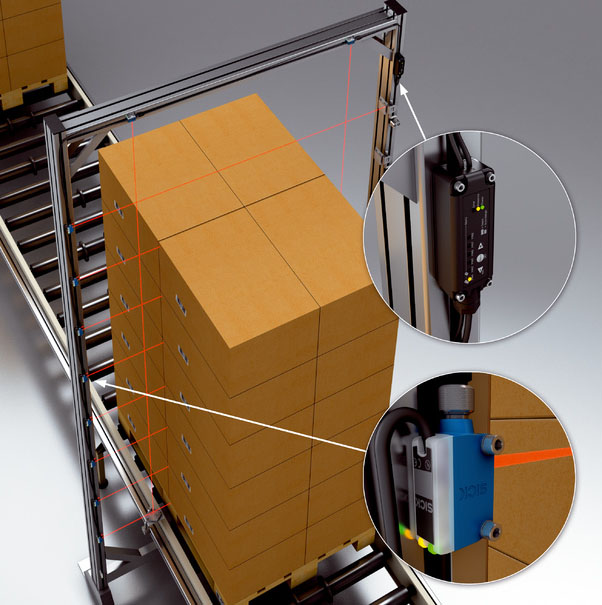

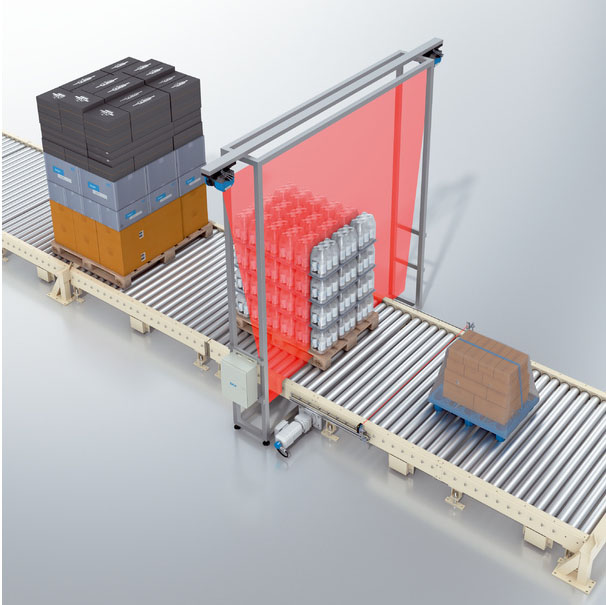

The LMS4000 2D-LiDAR sensor is particularly suitable for use in intralogistics, material handling and all areas where goods need to be analyzed and moved quickly and in a targeted manner. With the LMS4000, SICK offers you the ideal solution for measuring objects for their position, shape, volume or surface constitution as well as for evaluating and subjecting them to further processing. Regardless of the object's position in bins, cartons, on pallets, free or in contact with each other, the sensor measures accurately with high scanning density and wide dynamic range.

In short

• Accurate measurement, even with very dark or shiny objects

• Fine angular resolution for high density of measuring points

• Extremely fast measurement with 600 Hz and fast data transfer with Gigabit Ethernet

• Synchronization of devices without mutual interference

• M12 connections adapted to industry requirements

Your advantages

• Accurate measurement of small and large objects moving quickly regardless of their shape, color or surface makeup

• True-to-detail scanning of objects for great depth of field and wide dynamic range without external illumination or linear lasers

• Extension of the measuring range as required by mounting several devices next to each other without mutual interference

• Quick assembly, high availability, easy maintenance

Applications

application areas

• Measurement component in volume measurement systems in logistics and sorting centers

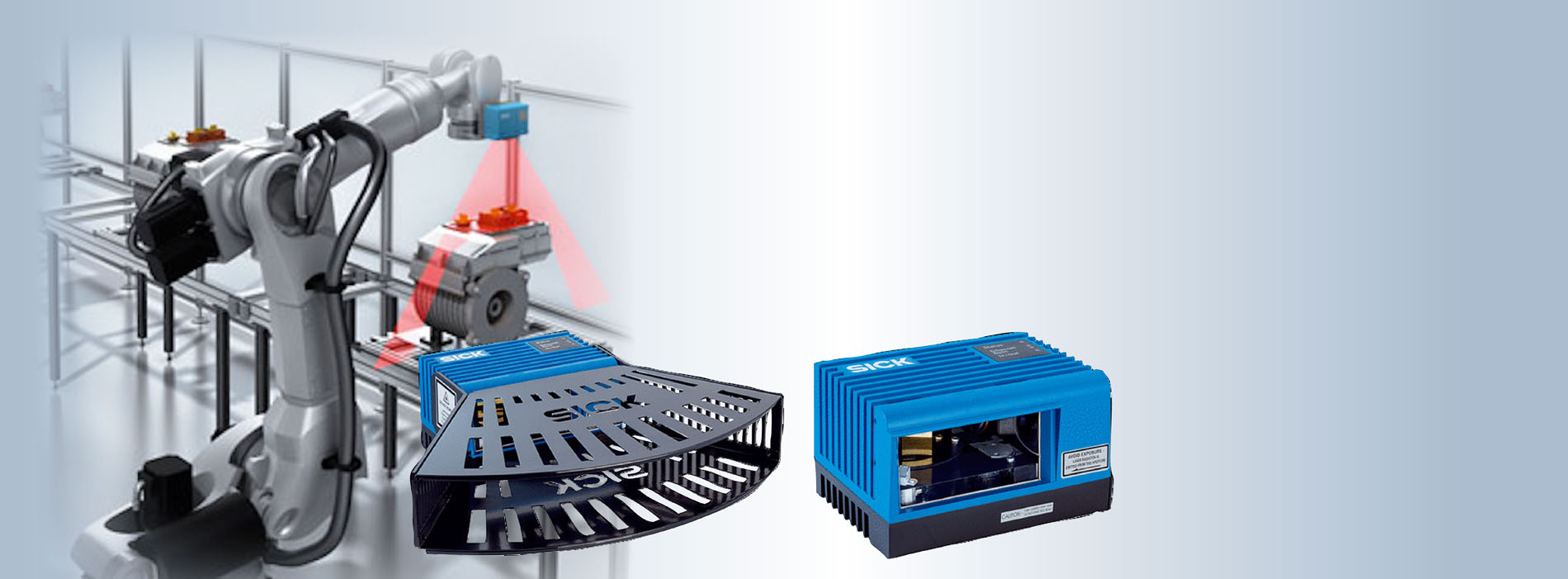

• Calculation of the dimensions and position of the object for automatic palletizing and depalletizing by robots

• Creation of 3D point clouds for any subsequent transformation

• Comparison of the shape and contours of objects for quality control

Need help ? You can communicate directly with our representatives, they will be able to advise you on the best SICK products suitable for optimizing your projects and installation for your company. Contact them!

Blog posts