SICK FTMg sensor

The FTMg thermal flow meter (abbreviation for Flow Thermal Meter for gases) stands for efficient energy management according to DIN EN ISO 50001. It helps plant operators to detect leaks in compressed air systems in good time and to plan maintenance. The FTMg offers integrated data monitoring and automatically records the measurement data of the last seven days. This allows changes and fluctuations in energy consumption to be reliably detected. Thanks to the transparency of its data, the flowmeter effectively supports the search for leaks in compressed air systems and helps to minimize energy losses and thus reduce costs.

Optimize energy efficiency and increase profitability by detecting and avoiding unnecessary energy consumption and leaks!

The FTMg offers you many mounting possibilities and easy handling. It is characterized by its light and compact construction. This means that it is easy to install, even in tight spaces. With its rotating screen, it can be installed in any position; upside down, sideways or at an angle.

The display can be rotated by 90°, so that the measured values can always be read comfortably, no matter where the sensor is installed in the line. Its operation is almost lossless, thanks to its straight measuring channel, the sensor flow minimizes the pressure loss in the pneumatic system caused by the measuring technology.

Flexible configuration

Different reference standards according to DIN or ISO can be selected easily with the FTMg. Even individually defined reference values are easy to set using the device. Configurable outputs also allow simple adaptation to the desired application.

Even the smallest leak in a compressed air system can result in high costs. Typical sources of leaks are leaking or defective piping, hoses, fittings, valves and screw or flange connections, to name a few.

If leaks in these areas remain undetected or ignored for long periods of time, the operating system can suffer reduced economic efficiency and financial losses. The larger the leak, the higher the costs are likely to be. The FTMg helps to reliably detect leaks, saving valuable energy and unnecessary expenses.

With integrated data monitoring and automated storage of the last seven days of data in the sensor, the FTMg reliably detects changes and fluctuations in energy consumption. With this data transparency, the sensor provides effective assistance in finding leaks in the compressed air system and helps to minimize energy losses as well as save money. Wear and tear or defects in mechanical components often lead to changes in the consumption system. The FTMg detects these deviations with its high measuring dynamics, which makes it possible to undertake maintenance or repair work at an early stage.

As a multifunctional flow sensor for pneumatic applications, the FTMg allows the measurement of eight parameters in one device. Including energy in kWh, it reliably detects the flow, pressure and temperature of pneumatic systems, making additional sensors unnecessary. In this way, it saves you money, especially when it comes to installation and maintenance. The combination of these last three measured values also gives you an overview of the condition of the compressed air line, thus increasing the reliability of your system.

The FTMg is not only equipped with digital and analog outputs, but can also transmit measurement data to the PLC via IO-Link. It also offers variants with Power over Ethernet (PoE) via an integrated web server. The sensor can be accessed via the network using a computer, tablet or smartphone. These options allow you to analyze consumption and plan maintenance intervals, regardless of location. The FTMg is therefore perfectly suited for condition monitoring and predictive maintenance. The integrated MQTT and OPC as well as the UA communication interfaces guarantee an optimal connectivity cloud.

Technical characteristics - Overview

- Measuring principle calorimetric (flow and temperature), piezoresistive (pressure)

- Medium Compressed air (air quality ISO 8573-1: 2010 [3: 4: 4]), helium, argon, nitrogen, carbon dioxide

- Output signal 1 analog output 4 mA ... 20 mA + 1 digital / analog output (PNP, NPN, push-pull, 4 mA ... 20 mA / switchable) + 1 digital output (PNP, NPN, push-pull switchable), IO-Link V1.1 (COM3 / 230K4 Baund) Ethernet TCP / IP, OPC UA, MQTT, integrated web server

- Nominal diameter of measuring tube DN 15 DN 20 DN 25 (depending on type)

IN SUMMARY

Product Description:

The FTMg thermal flowmeter measures gas flow and temperature as well as process pressure, making it a versatile and cost-saving tool. With high measuring dynamics and low pressure loss, it detects non-corrosive gases in an extremely energy-efficient manner. The high-contrast color display ensures easy operation of the FTMg and offers the possibility of displaying several measured values in a progress diagram. Internal data logging over a period of seven days and integrated statistical analysis allow even the smallest leaks in a pneumatic system to be detected. PoE facilitates web-based connections to a PC or cloud to make energy consumption transparent. All measurement data can be transmitted via IO-Link or switching and analog signals.

In short

• Measurement of compressed air and non-corrosive gases such as argon, helium, carbon dioxide and nitrogen

• Calorimetric measuring principle with a measurement accuracy of ± 3% of the measured value and ± 0.3% of the full scale measuring range

• Measurement of gas flow, temperature, process pressure and energy consumption with a single sensor

• Low pressure loss

• High measuring dynamics for cylinder and leak monitoring

Your advantages

• Transparent measurement of compressed pressurized air according to DIN EN 50001

• A complete overview of flow, pressure and gas temperature values increases system reliability.

• IO-Link or Ethernet interfaces (communication with OPC UA) for easy system integration and data access

• Cost savings through reduced energy consumption and increased production efficiency

• Intuitive parameterization with a large, high-contrast OLED display for fast and economical commissioning

• Single installation and commissioning for recording flow, pressure and temperature data

Application areas

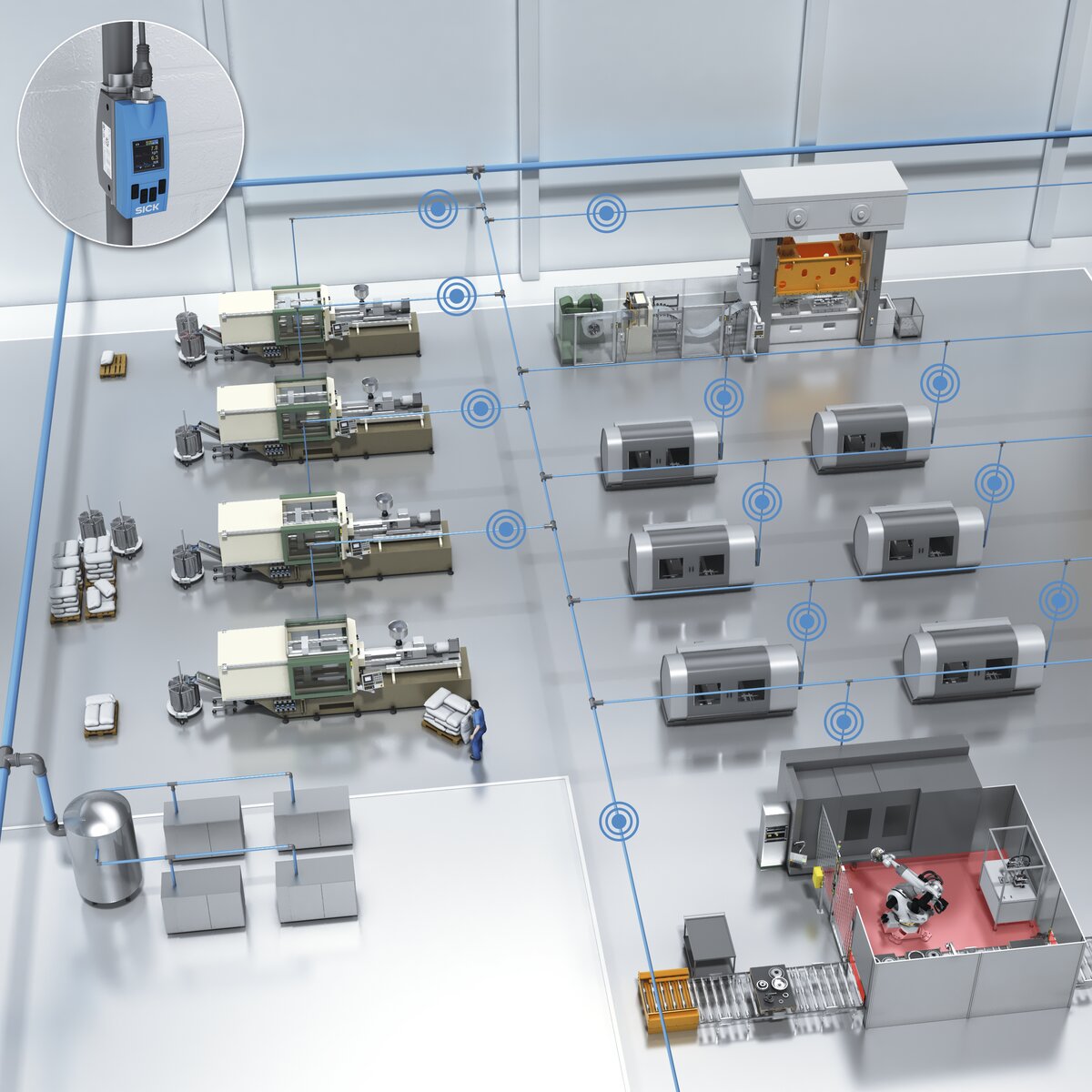

• Consumption control and leakage monitoring in compressed air systems

• Compressed air consumption measurement and leak detection in production

• Energy consumption monitoring of compressed air in the supply network

• Measurement of inert gases in modified atmosphere packaging in the food and beverage industry

• Flow measurement of non-corrosive gases such as Ar, He, CO2, N2

Need help ? You can communicate directly with our representatives, they will be able to advise you on the best SICK products adapted to your projects and your installations within your company. Contact them!

Contact details of team members

Blog posts