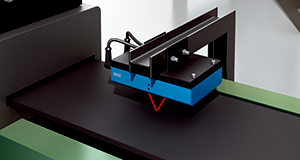

SPEETEC 1D motion sensor

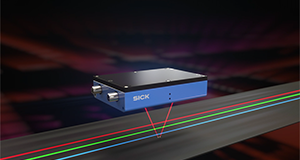

The wear and maintenance-free laser surface movement sensor SPEETEC 1D detects surface movements of objects without contact. It does not require any standard system or scale for detection. Its technology, based on the laser Doppler effect, allows the measurement of speed, length, direction of movement and position of objects on almost any surface. The sensor's non-contact measurement is particularly suitable for applications with soft, sensitive surfaces or surfaces that are damaged during tactile measurement. It allows non-contact motion data recording thanks to its compact dimensions and standardized TTL or HTL interface, it is also easy to integrate into new or existing installations and can be quickly commissioned. In addition, the SPEETEC 1D is ideally suited for coding applications in fast and dynamic processes for which other standard encoders are not suitable. The sensor can be monitored and its logic functions configured via an interface available on request.

In addition to being faster and more accurate, the SPEETEC 1D is significantly more economical than other laser speed sensors! Thanks to the laser class 1, it does not require any protective measures such as an enclosure, eye protection, safety zone protection or specially trained personnel for the integration of the device. The installation effort is minimal: just mount it and start it. The Doppler method of infrared laser measurement provides accurate velocity values up to 10 m/s with very high repeatability. Whether continuous materials or bulk parts, the high resolution of the laser allows a maximum resolution of 4 µm and the sensor can measure material lengths to the nearest millimeter over a distance of one meter. It can therefore offer maximum reliability for many applications.

The measuring system of the SPEETEC 1D is especially suitable for the measurement of particularly sensitive materials. Surfaces that show pressure marks, are damaged or subject to material changes due to the contact pressure of conventional wheel measuring systems can now be measured easily and reliably. Laser technology also prevents contamination of the surface of the material being measured. In addition to continuous material movements, the laser also measures goods movements simply and accurately.

On request, SPEETEC 1D is also available with a parameterization and diagnostic interface. This interface allows basic settings such as resolution, electrical interface and direction of travel to be set. In addition, logic functions for the analysis of external input signals and the resulting output signals can be activated and set. The diagnostic functions provide an overview of the current sensor status data and measurement results in the customer's application.

In short

- Non-contact measurement of speed, length and position without a measuring reference

- Compatibility with many materials, colors and surfaces

- Very high measuring accuracy and repeatability Class 1 laser

- Robust design, compact dimensions, low weight TTL or HTL interface

- Diagnostic and parameterization functio

Your benefits

- Offers new possibilities for measuring on sensitive, soft or smooth objects

- Optical sensors prevent damage or contamination of the surface to be measured and ensure high product quality

- Slip-free measurement increases measuring accuracy and thus optimizes productivity and process quality

- Thanks to laser class 1, no expensive laser protection measures or specially qualified personnel are required

- High measuring accuracy even in on-off operation and with small measuring lengths

- The configuration interface allows application and sensor diagnostics and parameterization

- Easy to install, wear and maintenance-free

Applications

- Consumer goods industry, e.g. packaging, digital printing

- Mechanical engineering, e.g. extrusion, metal processing, surface treatment

- Tire manufacturing

- Building materials industry, e.g. insulation material, dry construction

- Quality control

- Cutting processes

For more information on this product or to talk to us about one of your optimization projects. Contact one of our representatives, they will be able to advise you on the possible applications for your company or your project.

Blog posts