AZM40 of Schmersal

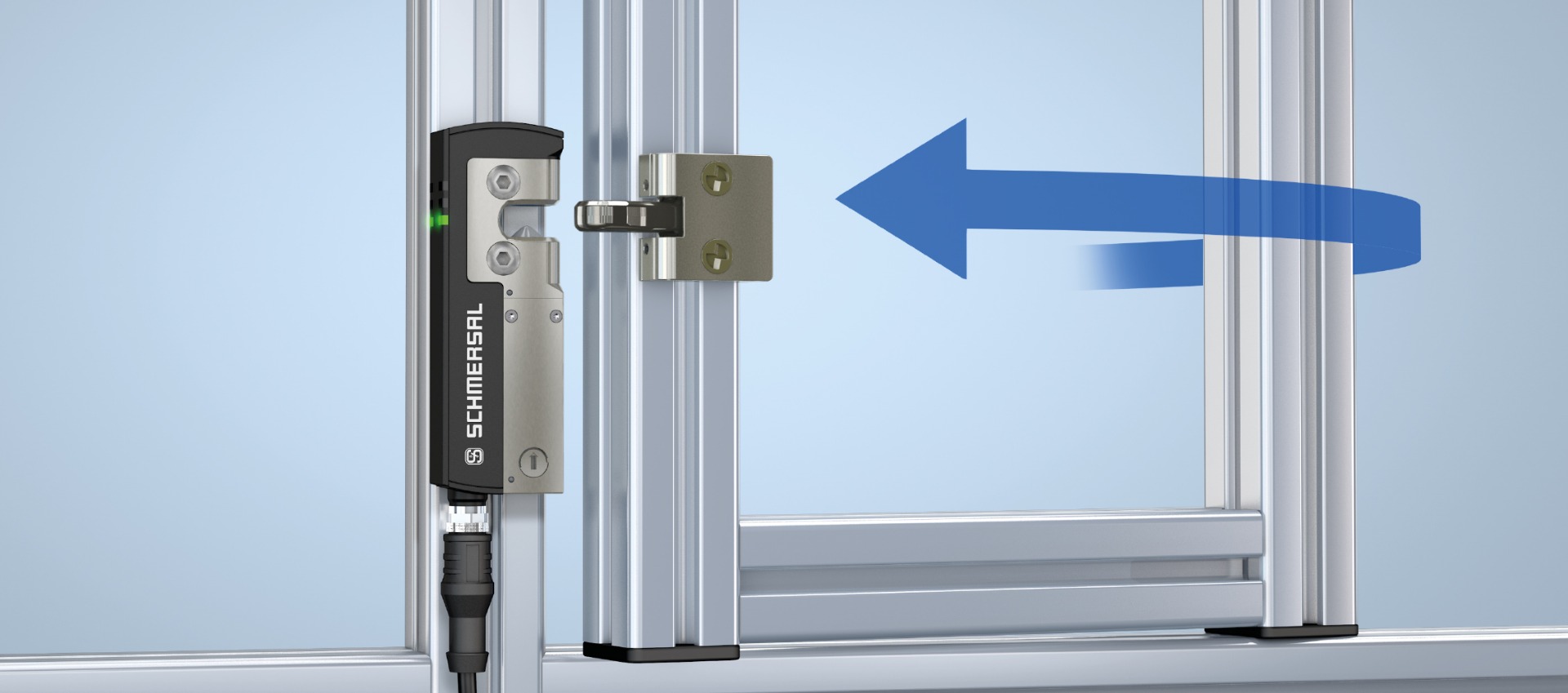

The AZM40 is the smallest electronic safety interlock in the world! It has a compact design and a high locking and holding force. It is particularly suitable for symmetrical mounting or mounting on profiles. It has LEDs visible on three sides that signal faults as soon as they occur and can be wired in series without dimming the safety function, thus enabling the guard to be monitored in both closed and locked mode.

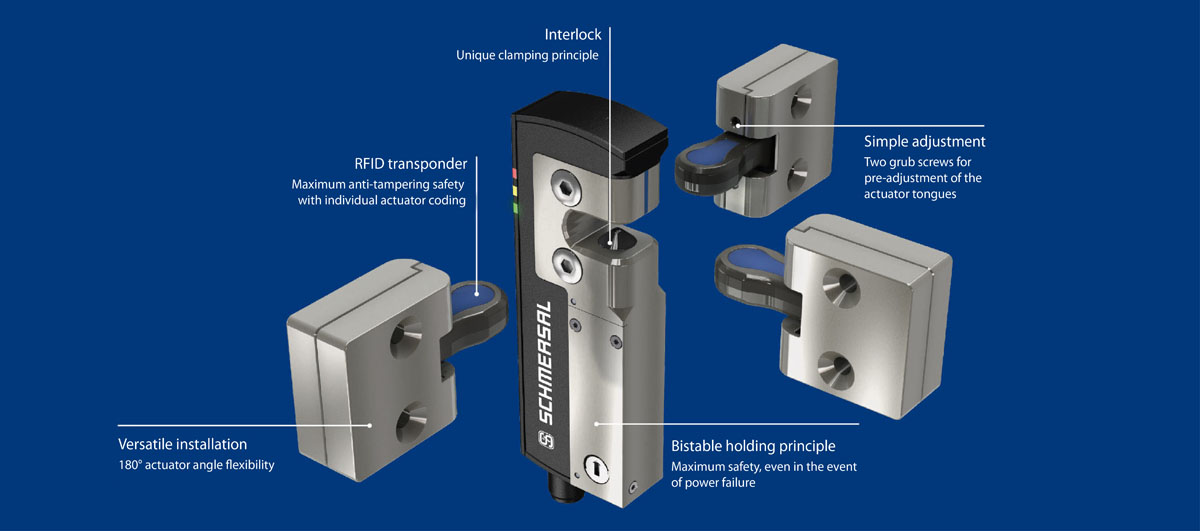

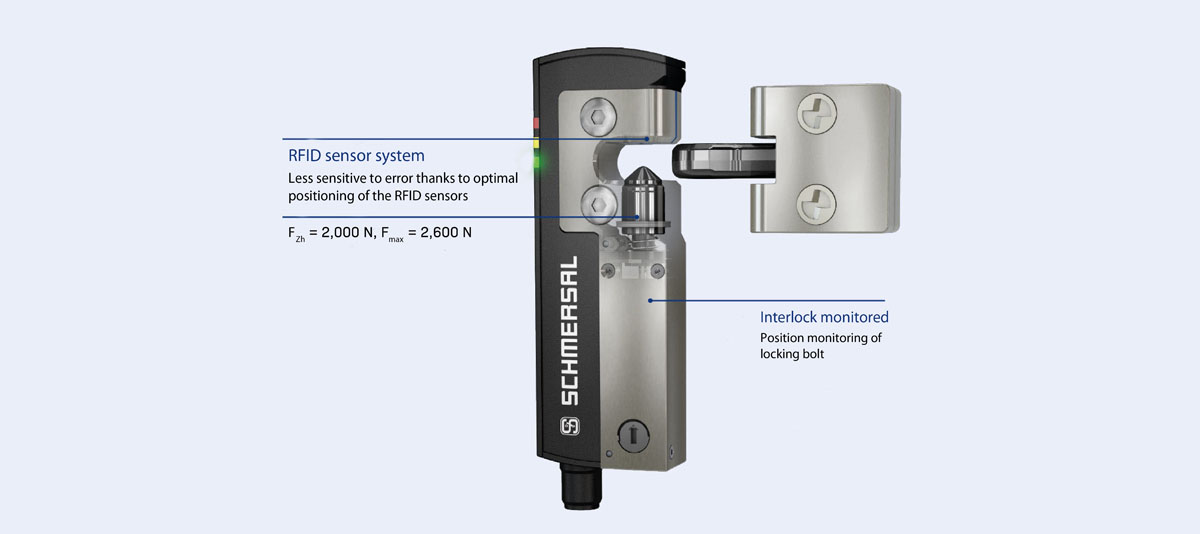

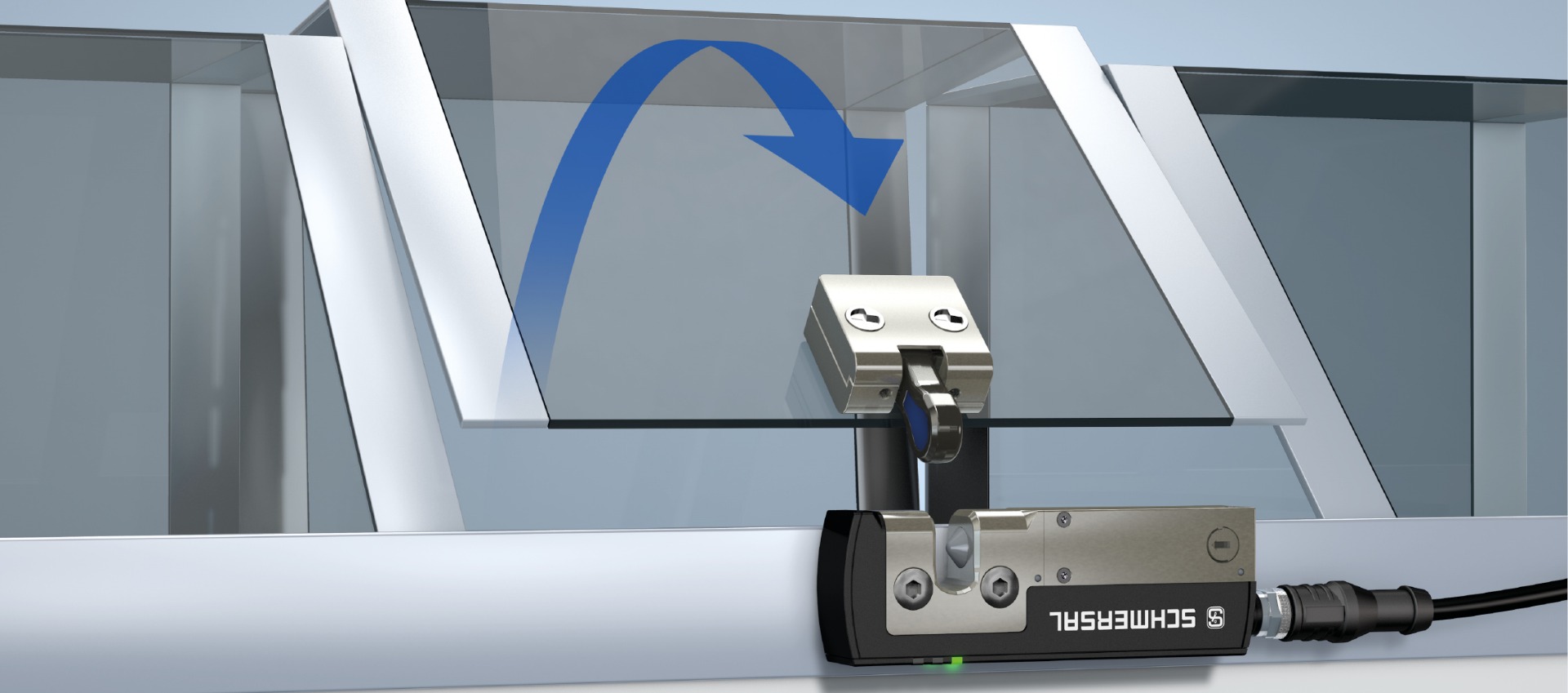

The AZM40 has a unique locking function! With its innovative clamping principle, the AZM40's conical locking bolt plunges into the actuator's countercircle, unlike a conventional interlock where the locking bolt passes completely through the actuator opening.

The clamping principle offers various advantages:

-

The latch bolt is only in contact with the actuator via a bevelled face, so lateral forces are easier to compensate.

-

The innovative locking mechanism allows the locking and unlocking of slightly braced doors and shutters.

-

This ensures smooth production processes and minimizes downtimes. Thanks to this locking principle, it is possible to install the RFID sensors in the center very close to the locking bolt.

Interference with other RFID fields or systems is then reduced, so that several devices can be mounted side by side. In addition, it allows you to achieve better compensation of a tilted or tilted actuator, which will result in increased machine availability. Thanks to the central arrangement of the sensors, the AZM40 can also be concealed, e.g. in a profile. For this purpose, no additional openings are required to establish the RFID communication. Thus, there are no interferences in the detection area between the profile walls.

The AZM40 is also equipped with a bistable interlocking principle. This means that the interlock retains the last interlocking state in the event of a power failure. This guarantees safety in every mode of operation of the machine, since in the event of dangerous inertial movements, the interlocking state of the safety guard is retained even after a loss of power supply. In addition, the bistable interlocking principle reduces energy consumption.

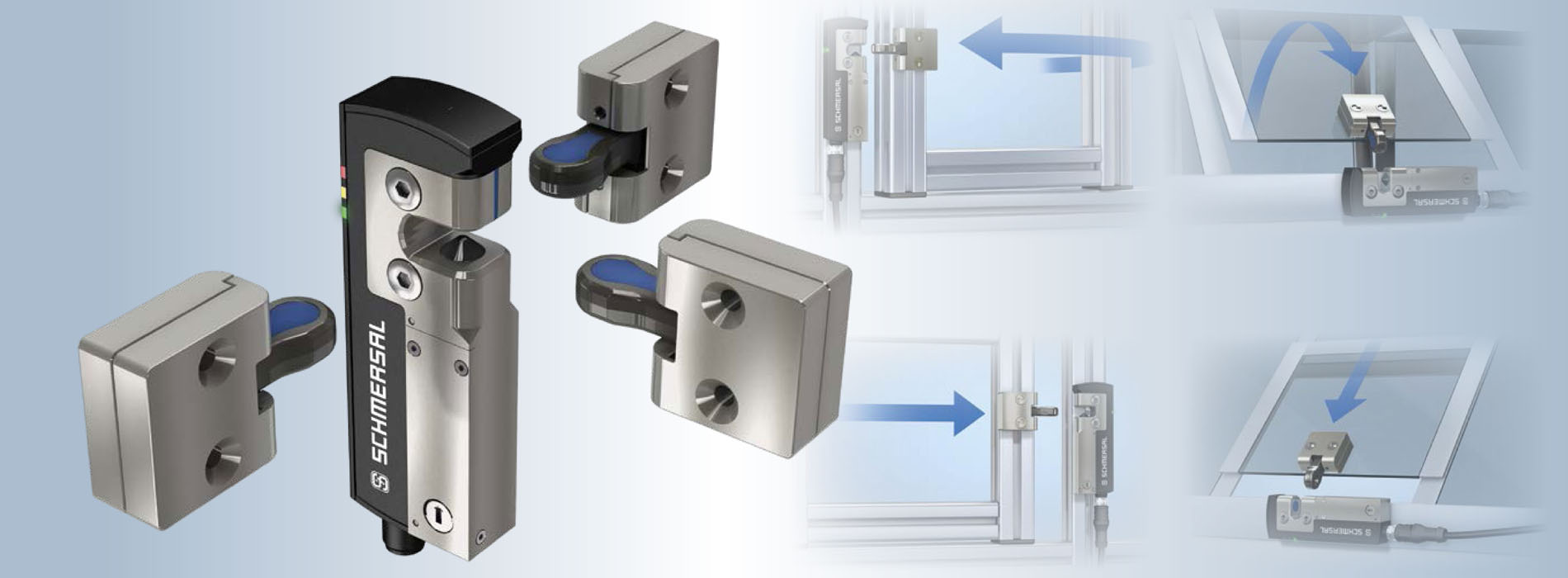

Also featuring a very high angular flexibility of up to 180°, the actuator can continuously approach the AZM40, so the interlock can be used with dampers that do not close at a 90° angle or open upward at a 45° angle. This angular flexibility also allows for easy installation of the interlock in tight, hard-to-reach spaces.

Depending on the desired application, two variants of the AZM40 are possible.

- For personal protection or equipment protection. In this variant, the safety outputs are already activated when the safety guard is closed. The guard locking is not mandatory with this device. Please note that in this type of application, the Safety Locking Device retains the last position of the bolt in the event of a power failure. The safety outputs of the AZM40Z Safety Locking Device are only activated when the guard is closed AND locked.

- If the locking devices are tampered with, the machine can no longer be used under the conditions prescribed by the manufacturer. This can lead to considerable risks for the operator. If tampering cannot be ruled out by changing or adding operating modes to the machine (e.g. degraded mode), the manufacturer has only one solution: to make tampering with the interlocking device more difficult or even impossible.

There is also a third variant that allows an unlimited number of actuators to be relearned by applying a specific procedure. During the learning process, a ten-minute waiting time prevents the short-term change of an actuator and increases the anti-fraud protection. This allows the user to choose the most appropriate level of coding and tampering protection for his application.

Areas of application:

The AZM40 Safety Locking Device can be mounted in confined spaces and in a wide variety of positions, making it suitable for many applications. It can be used on packaging machines, wood processing machines and in the pharmaceutical industry. It is particularly suitable for mounting on machines with small flaps, but also on pivoting or sliding doors.

In conclusion, thanks to the numerous integrated monitoring functions, the AZM40 can be connected in series with all Schmersal electronic safety devices. This considerably simplifies the monitoring of several guards in an installation, while significantly reducing costs. The series-connected electronic safety interlocks monitor themselves and meet the requirements of category 4 according to ISO 13849. It is now easier to detect faults in a chain or a cross-circuit in the cables from the safety outputs to the electrical box. In addition, cyclic self-tests ensure that the guard locking and the redundant safety outputs are functioning correctly. A fault at a safety output, but also a cross-circuit, is indicated by different colors/flashes of the integrated three-color diagnostic LEDs. General faults, such as too high an ambient temperature, are also detected and indicated.

For more information on this product or to talk to us about one of your optimization projects. Contact one of our representatives, they will be able to advise you on the possible applications for your company or your project.

Contact details of team members

Blog posts